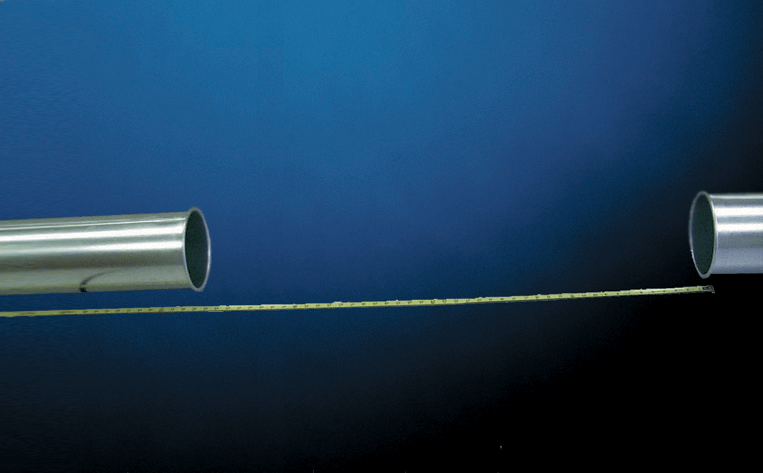

STEP ONE: Measure the distance you want to span.

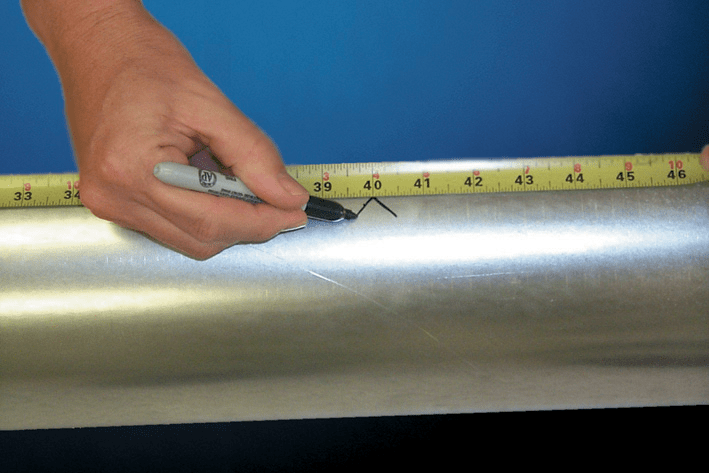

STEP TWO: Mark the desired distance to be spanned minus 4”.

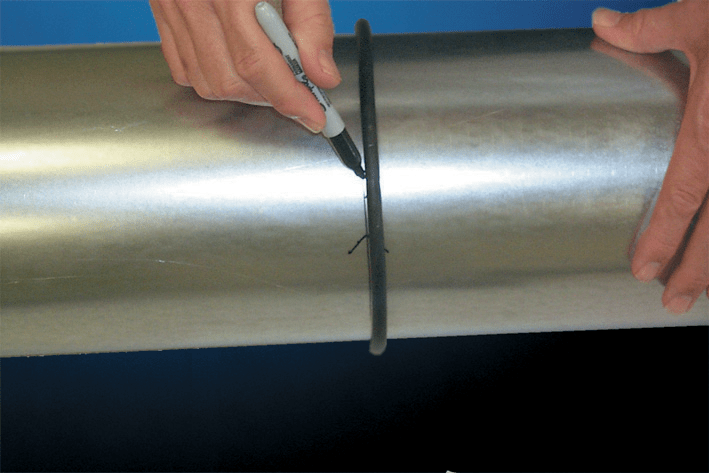

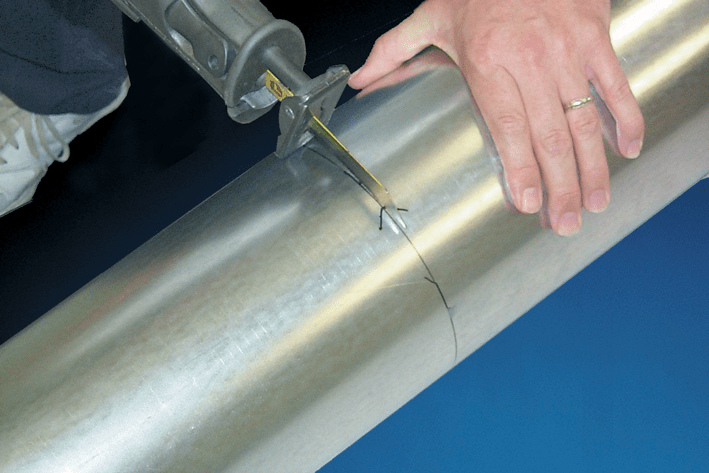

STEP THREE: Use the provided O-Ring and make a mark for the cut.

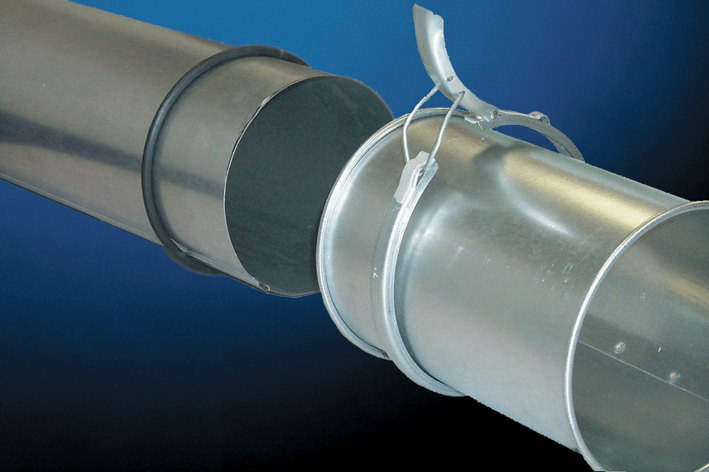

STEP FIVE: Place the O-ring on the cut piece of QF pipe and slide a Quick-Fit Sleeve over the cut piece. Be sure that the 11" Quick-Fit Sleeve is downstream (closest to the dust collector) of the cut piece.

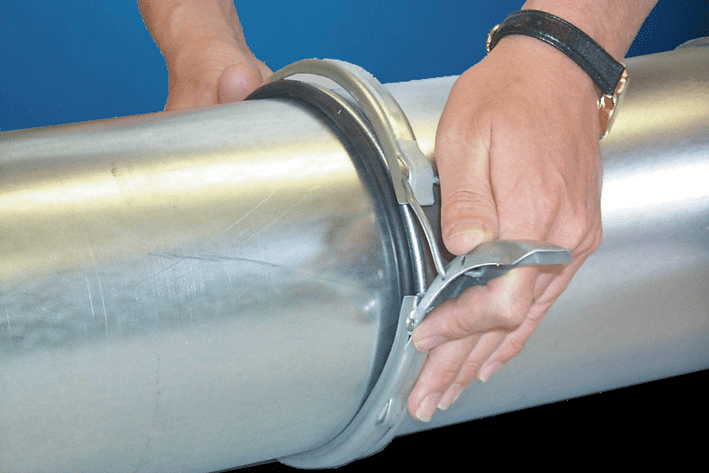

STEP SIX: Snap the QF Clamp over the O-Ring and one end of the Quick-Fit Sleeve.

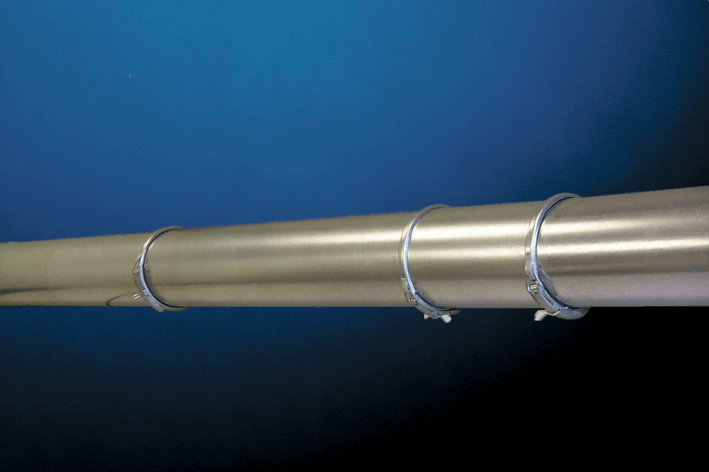

Finished connection with the Quick-Fit Sleeve

Once in place, you can re-adjust the length of the assembly by releasing the QF Clamp and changing the length of the duct that is inserted into the Quick-Fit Sleeve.

IMPORTANT SAFETY NOTE: To ensure a strong, safe and stable system, there must always be at least four inches of duct inserted into the Quick-Fit Sleeve.