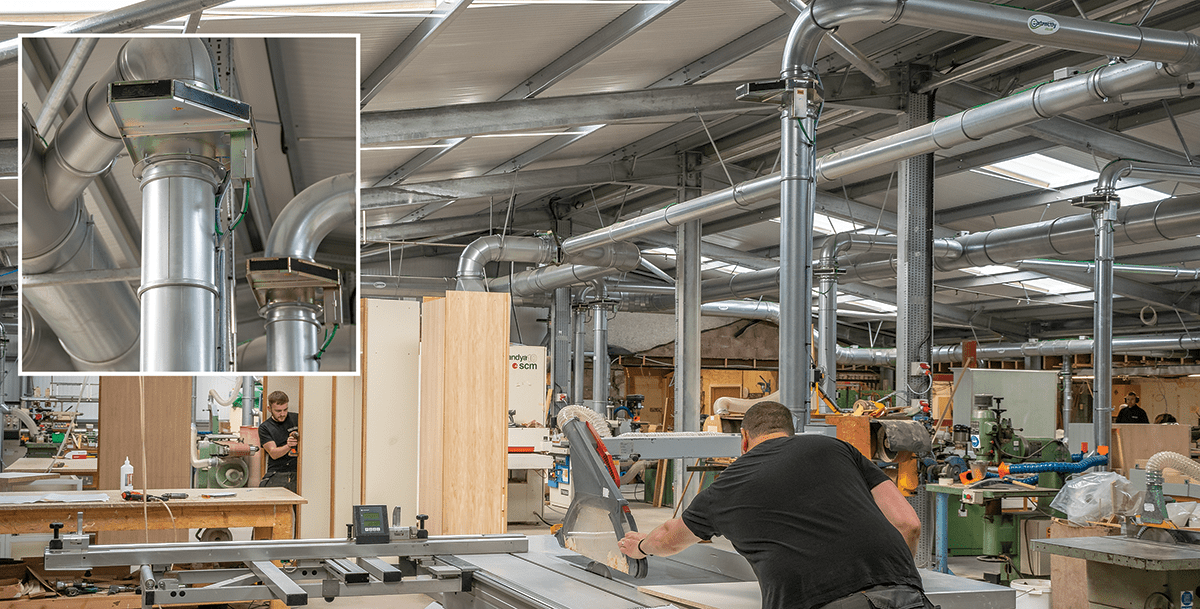

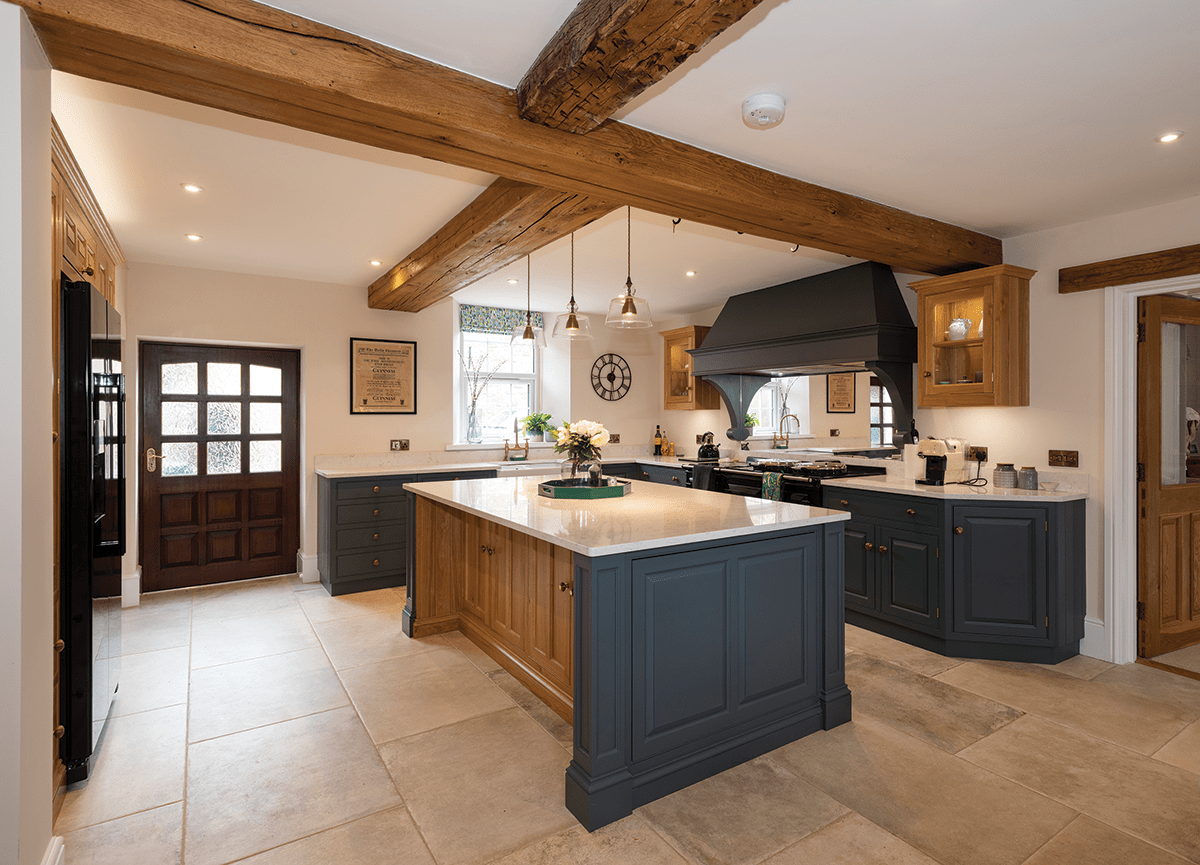

When Thwaite Holme, manufacturer and installer of quality fitted kitchens and bedrooms, expanded their premises, they contacted one of our partners for help. Our dedicated partner used Nordfab ducting throughout the new building and enabled the factory layout to be reorganized to optimise workflow, giving Thwaite Holme a 35% energy consumption reduction.

When the Nordfab partner was contacted they quickly realized after been shown the newly extended factory that the task was going to involve much more than an update of the ductwork arrangement. After a brief inspection of the factory, our partner carried out a comprehensive evaluation of the extraction requirements, including a full energy-saving survey. With around 40 machines requiring extraction, and yet only a small number of them ever in use at any given time, the potential savings were substantial.

Nordfab is proud to have partners who are extremely knowledgeable in LEV and can provide smart ductwork design, supply and install products. Thwaine Holme managed to reduce their energy consumption with 66,000 kWh a year, saving thousands of pounds every year on electricity costs when they were provided:

It looks like you're coming from United States.

Would you like to go to the United States site?